8,000-10,000 pcs/h

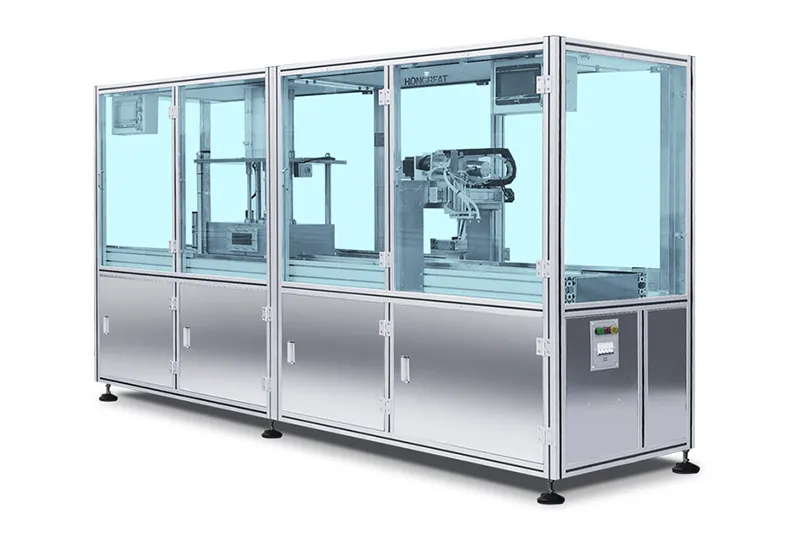

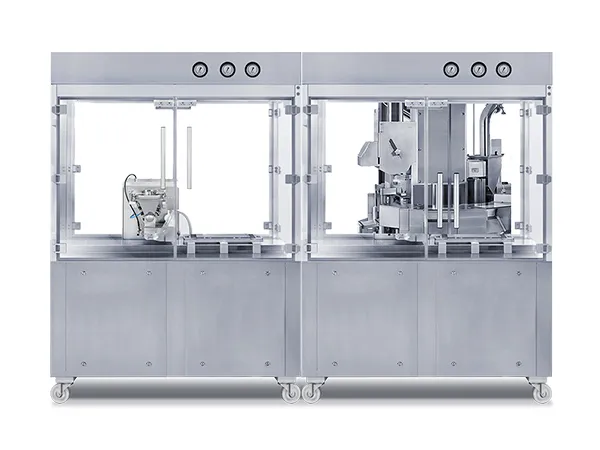

Automatic PRP Blood Collection Tube Assembly Line

Blood collection tube assembly machine for PRP (platelet-rich plasma) tubes

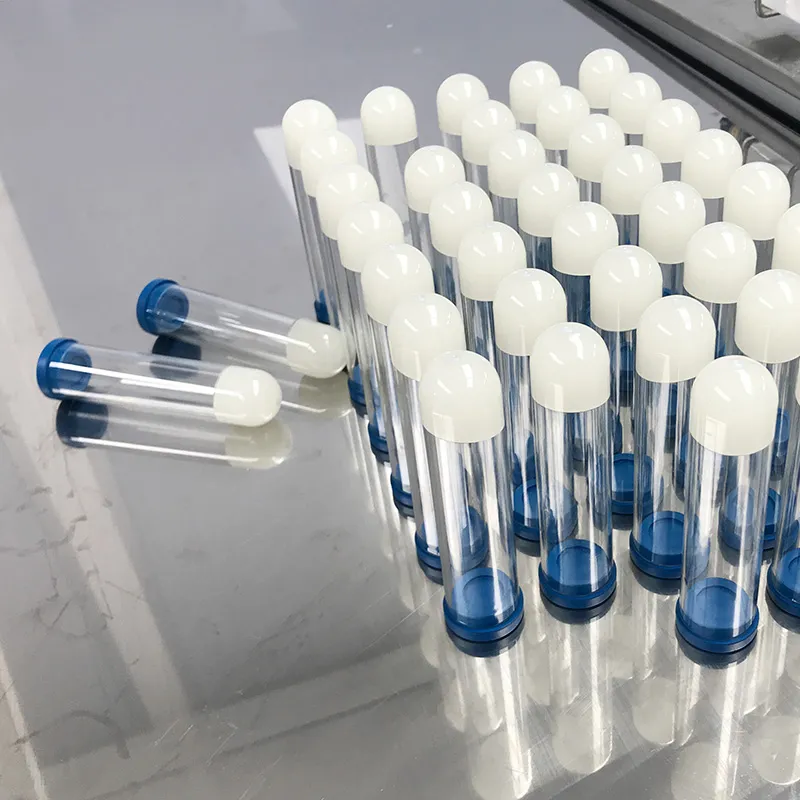

Finished Product Samples

The demand for platelet-rich plasma (PRP) collection tubes has grown significantly in both medical and aesthetic applications. This automatic assembly line is designed to meet that demand, producing 8,000 to 10,000 PRP vacuum tubes per hour. The blood collection tube assembly system is fully automated, efficiently handling the assembly of 16×100mm and 16×125mm tubes. From tube loading to vacuuming and heat shrink packaging, this line ensures high-quality production with consistent output.

Work Flow

- Tube loading

- Inversion detection

- Separation gel dosing

- Separation gel centrifuge

- Additive dosing

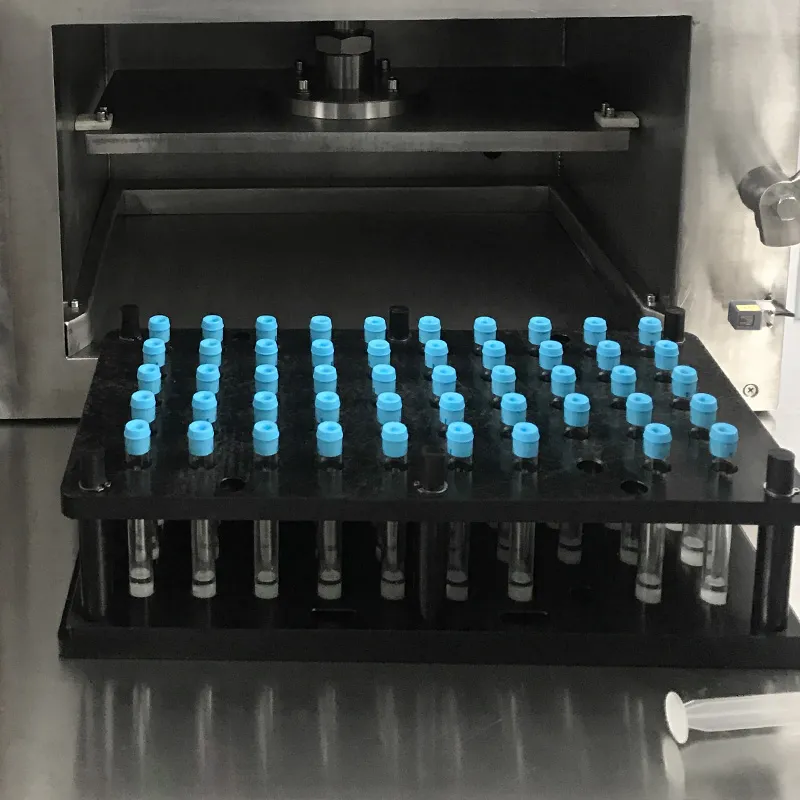

- Capping

- Vacuuming

- Labeling

- Inner packaging

- Heat shrink packaging

- Completion

Technical Specifications

| Production capacity | 8,000-10,000 pcs/h |

| Tube size | Ø16×100mm, Ø16×125mm, customizable (available in PET and glass) |

| Cap size | As per client’s samples |

| Control system | PLC control with touch screen |

| Additive dosing system | Sodium citrate/ACD solution: 10 sets of precision ceramic pump (100-900μL ±6%) |

| Separation gel: 10 sets of precision ceramic pump (0.6-2g ±10%) | |

| Detection system | Inverted tube detection before additive dosing |

| Alarm for shortage of foam trays | |

| Vacuum degree | Vacuum tube: 0 ~ -95Kpa ±3% |

| Equipped with Leybold vacuum pump (Germany) and SMC vacuum control system (Japan) | |

| Air consumption | Max. 1 m³/min Air supply pressure P:0.7Mpa≤P≤1Mpa |

| Power | 20kW/AC380V |

We provide efficient assembly solutions tailored to your medical device needs

Get in Touch

About HONGREAT

Your Reliable Partner for Blood Collection Tube Assembly Solutions

- 220Partner of over 220 companies globally

- 40Exporting to more than 40 countries worldwide

- 20Over 20 years of experience in manufacturing blood collection tube assembly equipment

- 1010+ years dedicated to after-sales service

- 19Holder of 19 patents in blood collection tube machine technology