Semi-Automatic Blood Culture Bottle Assembly Line

Semi-auto assembly machine for blood culture bottles

Precision spraying is an essential step in medical production lines, ensuring consistent application of bonding agent to critical components like bottle bases. This particular machine features a specialized ceramic spray system, engineered to deliver precise doses with a high level of control, while maintaining smooth operation and minimal downtime.

Technical Specifications

- Capacity: 3,000 pcs/h

- Bottle size: Customizable based on sample specifications

- Dosing volume: 20-50μL per application

- Accuracy: ±6%

- Power: 1KW/AC220V

- Air consumption: 0.2m³/min

- Overall dimensions (L×W×H): 600×1100×1400mm

Features

- Six HONGREAT precision ceramic spraying systems ensure accuracy and efficiency

- Ultra-fine atomization nozzles with adjustable particle size, providing even and thorough coverage

- Independent air control units enhance customization for different production needs

- Built-in automatic cleaning system for reduced maintenance

- Agent storage monitoring and low-level alarms safeguard against production delays

For precise gel filling applications, particularly those involving sensing film, this gel filling machine is designed to ensure controlled and efficient production. The advanced system includes an automatic gel application setup and a low-temperature vacuum mixing tank, which maintains the gel’s consistency throughout the process.

Technical Specifications

- Capacity: 800-1000 pcs/h (Actual speed may vary based on fill volume and gel viscosity)

- Filling accuracy: ±10%

- Power: 9kW/AC380

- Overall dimensions (LxWxH): 1650×950×1800mm

Features

- Gel filling range of 1-10 grams per unit for flexibility in production

- Integrated automatic gel application system for consistent and reliable results

- Low-temperature vacuum mixing tank to ensure stable gel quality during application

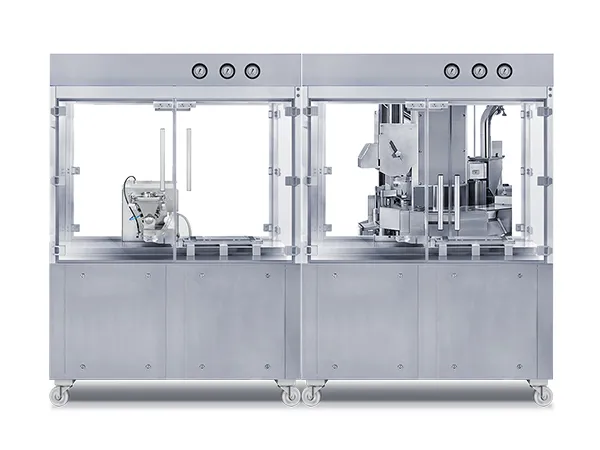

For applications requiring precise vacuum and gas filling, an advanced solution integrates inert gas injection and vacuuming capabilities. The gas filling and vacuuming machine has a vacuum chamber, programmable control systems, and precision technology to fill bottles with non-reactive gases like nitrogen and argon. By ensuring a stable environment inside the vacuum chamber, the process facilitates uniform filling and sealing for blood culture bottles.

Technical Specifications

- Production capacity: 144 bottles per cycle

- Suitable bottle size: Height less than 100mm

- Tray size: 520×520mm

- Special gas filling: 2 types (flammable or explosive gases prohibited)

- Vacuum degree: -10 to -75 Kpa

- Vacuum degree tolerance: +/-5%

- Power: 3kW/AC380V

- Air consumption: 0.3m³/min

- Overall dimensions (L×W×H): 1150×1500×1900mm

Process

- Set the desired vacuum level for the bottle

- Configure the gas vacuum parameters

- Choose the cycle mode and define the number of cycles

- Initiate the vacuum pump

- Open the gas valve for filling

- Close the vacuum chamber and start the automated cycle

Once the vacuum chamber is closed, the system begins by reaching the predefined vacuum level and stabilizing it. Then, the special gas valve automatically opens to inject the necessary gas, ensuring the correct ratio is maintained. After reaching the desired vacuum level and final volume, the vacuum stabilizes again, the capping process is completed, and the chamber door opens, resulting in the finished product.

Our capping machine is designed for automatically capping blood culture bottles with aluminum caps. It ensures precise and efficient capping, significantly reducing manual labor while maintaining high accuracy and consistency.

Technical Specifications

- Production capacity: 800-1000 pcs/h

- Qualified rate: More than 99%

- Power: 3.5kW/AC220V

- Overall dimensions (L×W×H): 2200×1450×1600mm

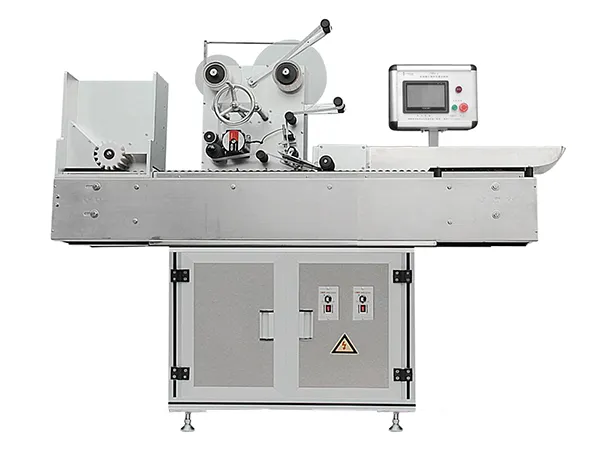

Technical Specifications

- Production capacity: 10,000-12,000 pcs/h

- Suitable bottle size: Based on sample specifications

- Applicable label types: Opaque and transparent labels

- Label size: Based on sample specifications

- Power: 500W/AC220V

- Overall dimensions (L×W×H): 2200×700×1500mm

Features

- Controlled by a PLC program

- Equipped with a stepper motor for label feeding

- Optical sensors for precise label and bottle detection

- 220Partner of over 220 companies globally

- 40Exporting to more than 40 countries worldwide

- 20Over 20 years of experience in manufacturing blood collection tube assembly equipment

- 1010+ years dedicated to after-sales service

- 19Holder of 19 patents in blood collection tube machine technology