2,000-3,000 pcs/h

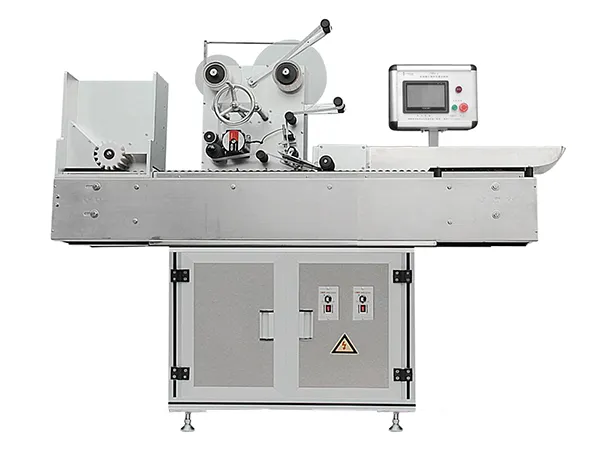

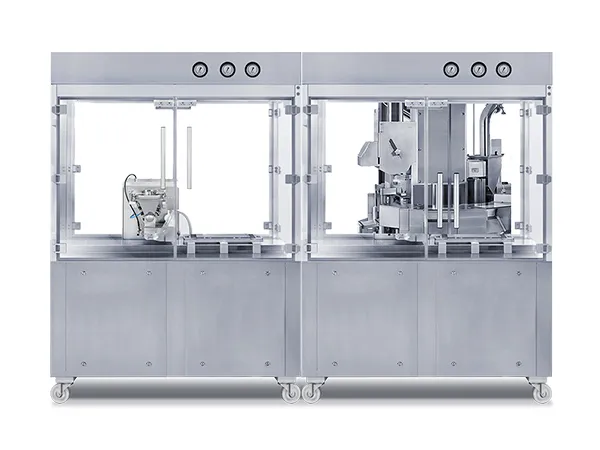

S2 Disposable Virus Sampling Tube Assembly Line

Virus sample collection tube assembly machine for VTM (virus transport medium) tubes

S2 Disposable Virus Sampling Tube Assembly Line

Virus sample collection tube assembly machine for VTM (virus transport medium) tubes

-

Production capacity 2,000-3,000 pcs/h

-

Tube loading Equipped with a vibrating bowl for automatic tube loading

-

Additive dosing Adjustable additive volume from 1-10ml, using a high-precision ceramic pump with tolerance of ±3%

Finished Product Samples

With a capacity of 2,000 to 3,000 tubes per hour, this assembly line is designed for the efficient production of disposable virus sampling tubes. The assembly system automates each stage of the process, ensuring precision and consistency in every tube. From tube loading to reagent dosing (virus preservation solution) and capping, this line offers reliable output tailored to the needs of small or medium-scale manufacturing plants.

Work Flow

- Automatic tube loading

- Additive dosing (virus preservation solution)

- Cap loading

- Capping

- Finished product output

Technical Specifications

| Station | Description | Configuration |

| Tube loading | Equipped with a vibrating bowl for automatic tube loading | |

| Additive dosing | Adjustable additive volume from 1-10ml, using a high-precision ceramic pump with tolerance +/-3% | 2 sets of dosing systems |

| Cap loading | Equipped with a vibrating bowl for automatic cap loading | with detection for lack of cap in the feeding bowl |

| Capping | Capping functionality ensures tightening of caps while avoiding damage | Includes functionality for inspecting finished products |

| Equipped with laminar flow hood and UV sterilization lamp, with a production capacity of approximately 2,000-3,000 units per hour. | ||

Related Products

We provide efficient assembly solutions tailored to your medical device needs

Get in Touch

About HONGREAT

Your Reliable Partner for Blood Collection Tube Assembly Solutions

- 220Partner of over 220 companies globally

- 40Exporting to more than 40 countries worldwide

- 20Over 20 years of experience in manufacturing blood collection tube assembly equipment

- 1010+ years dedicated to after-sales service

- 19Holder of 19 patents in blood collection tube machine technology