2,000-4,000 pcs/h

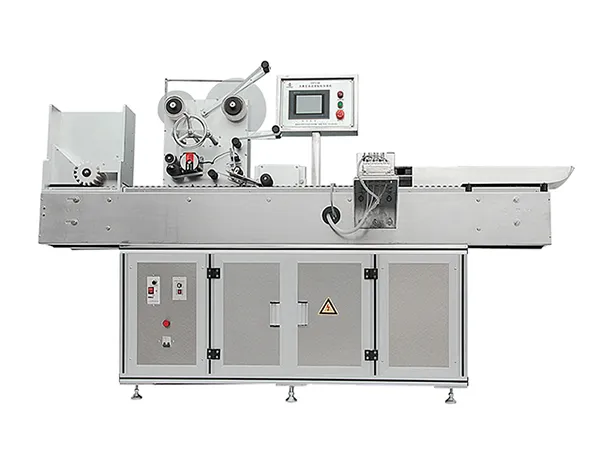

Non-Vacuum Blood Collection Tube Assembly Line

Blood collection tube assembly machine for non-vacuum blood collection tubes

Finished Product Samples

The medical supplies assembly line we offer is tailored for the production of disposable non-vacuum blood collection tubes, focusing on tube sizes 13×75mm and 13×100mm. The system is designed to provide consistent performance, ensuring accurate dosing and reliable assembly. By automating key steps in the process, it helps manufacturers meet the demands of the medical industry while maintaining efficiency and quality.

Work Flow

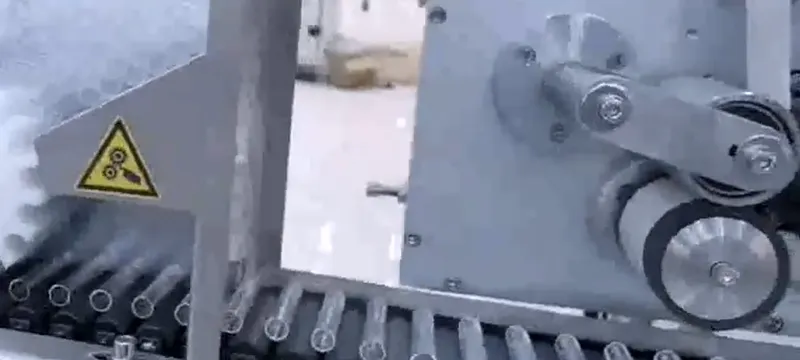

- Labeling

- Additive dosing (EDTA, heparin, clot activator)

- Additive drying

- Capping

- Completion.

Technical Specifications

| Model | 150BF |

| Production capacity | 2,000-4,000 pcs/h |

| Tube size | Ø13×75mm, Ø13×100mm, customizable |

| Cap size | As per client’s samples |

| Control system | PLC control with touch screen |

| Additive dosing system | K2/K3 EDTA: 4 sets of precision ceramic pump |

| Blood clot activator (BCA): 4 sets of precision ceramic pump | |

| Additive drying system | PTC dust-free drying machine (8 nozzles) |

| Air consumption | Max. 1 m³/min Air supply pressure P:0.7Mpa≤P≤1Mpa |

| Power | 10kW/AC380V |

Related Products

We provide efficient assembly solutions tailored to your medical device needs

Get in Touch

About HONGREAT

Your Reliable Partner for Blood Collection Tube Assembly Solutions

- 220Partner of over 220 companies globally

- 40Exporting to more than 40 countries worldwide

- 20Over 20 years of experience in manufacturing blood collection tube assembly equipment

- 1010+ years dedicated to after-sales service

- 19Holder of 19 patents in blood collection tube machine technology