3,000-4,000 pcs/h

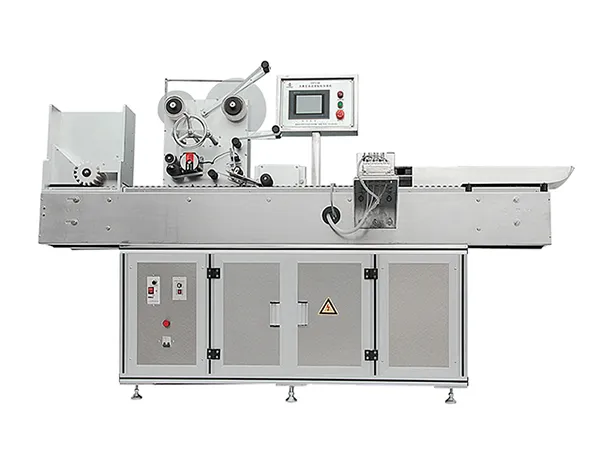

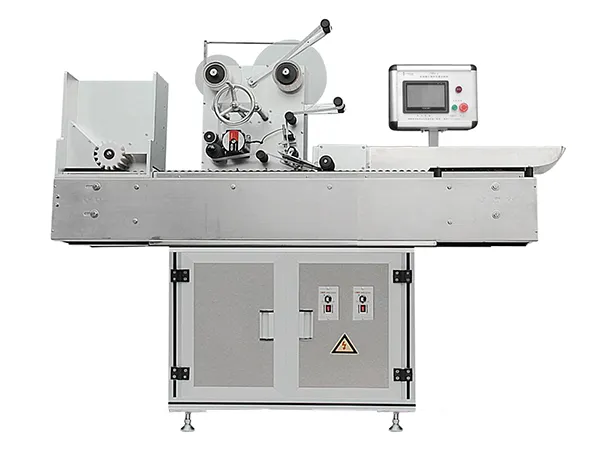

Non-Vacuum Blood Collection Tube Assembly Line

Blood collection tube assembly machine for non-vacuum blood collection tubes

Finished Product Samples

Designed for high-efficiency assembly of non-vacuum blood collection tubes, this assembly system operates at a speed of 3,000 to 4,000 tubes per hour. Equipped with precision ceramic pumps, it ensures accurate additive dosing. It delivers precise and reliable manufacturing for various non-vacuum blood collection tubes.

Work Flow

- Tube loading

- Additive dosing (EDTA, heparin, clot activator, sodium citrate)

- Additive drying

- Capping

- Completion

Technical Specifications

| Model | 60BF |

| Production capacity | 3,000-4,000 pcs/h |

| Tube size | Ø13×75mm, Ø13×100mm or customizable (available in PET, PP, glass) |

| Cap size | As per client’s samples |

| Control system | PLC control with touch screen |

| Additive dosing system | K2/K3 EDTA: 4 sets of precision ceramic pump |

| Blood clot activator (BCA): 4 sets of precision ceramic pump | |

| Sodium citrate: 4 sets of precision ceramic pump (100-650μL ±6%) | |

| Additive drying system | PTC dust-free drying machine (8 nozzles) |

| Air consumption | Max. 1 m³/min Air supply pressure P:0.7Mpa≤P≤1Mpa |

| Power | 12kW/AC380V |

Related Products

We provide efficient assembly solutions tailored to your medical device needs

Get in Touch

About HONGREAT

Your Reliable Partner for Blood Collection Tube Assembly Solutions

- 220Partner of over 220 companies globally

- 40Exporting to more than 40 countries worldwide

- 20Over 20 years of experience in manufacturing blood collection tube assembly equipment

- 1010+ years dedicated to after-sales service

- 19Holder of 19 patents in blood collection tube machine technology