15,000-18,000 pcs/h (with Pre-Labeling)

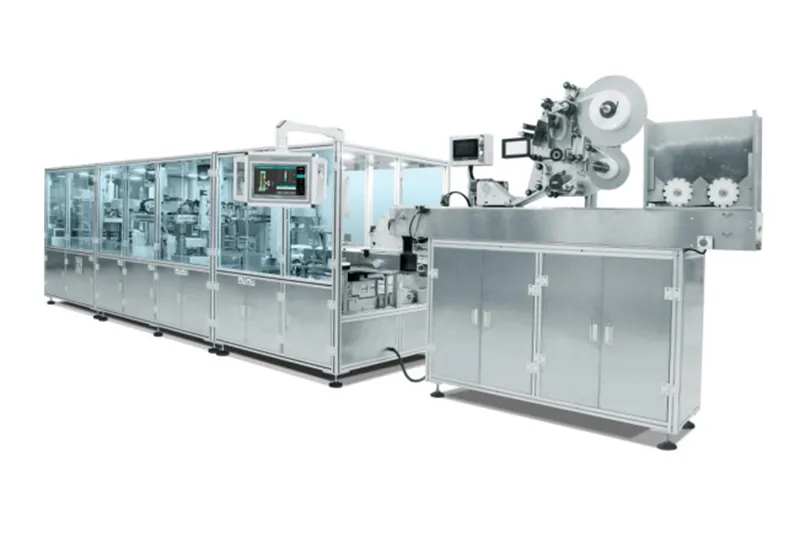

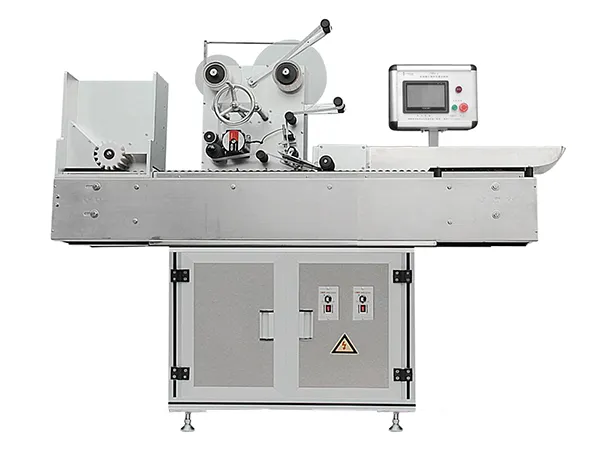

Automatic Vacuum Blood Collection Tube Assembly Line

Automatic production line for assembling vacuum & non-vacuum blood collection tubes

Automatic Vacuum Blood Collection Tube Assembly Line

Automatic production line for assembling vacuum & non-vacuum blood collection tubes

-

Production capacity 15,000-18,000 pcs/h

-

Tube size Ø13×75mm, Ø13×100mm, Ø16×100mm, customizable

(available in PET, PP, glass) -

Cap size As per client’s samples

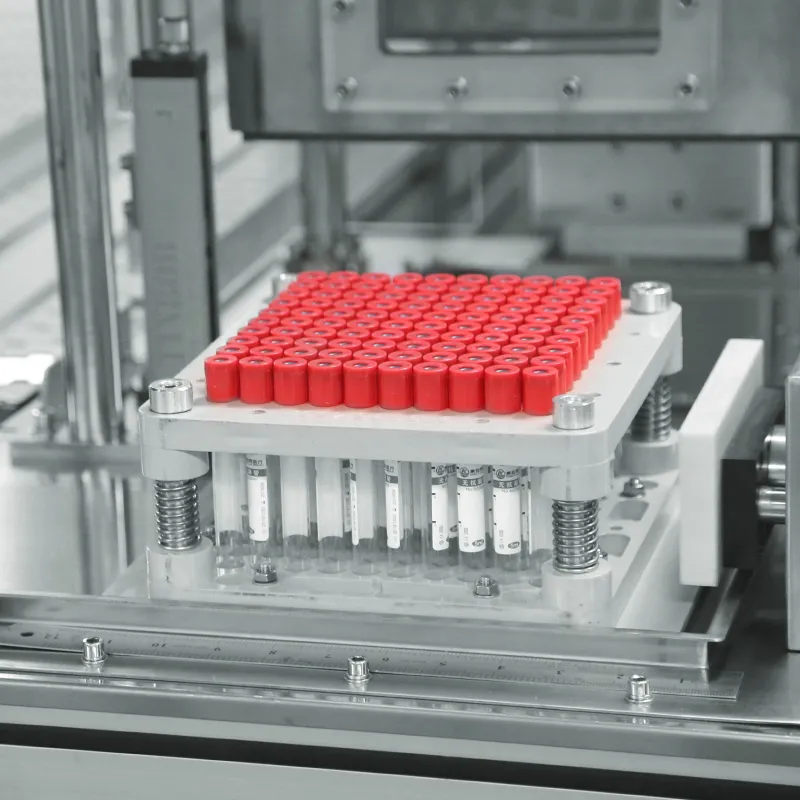

Finished Product Samples

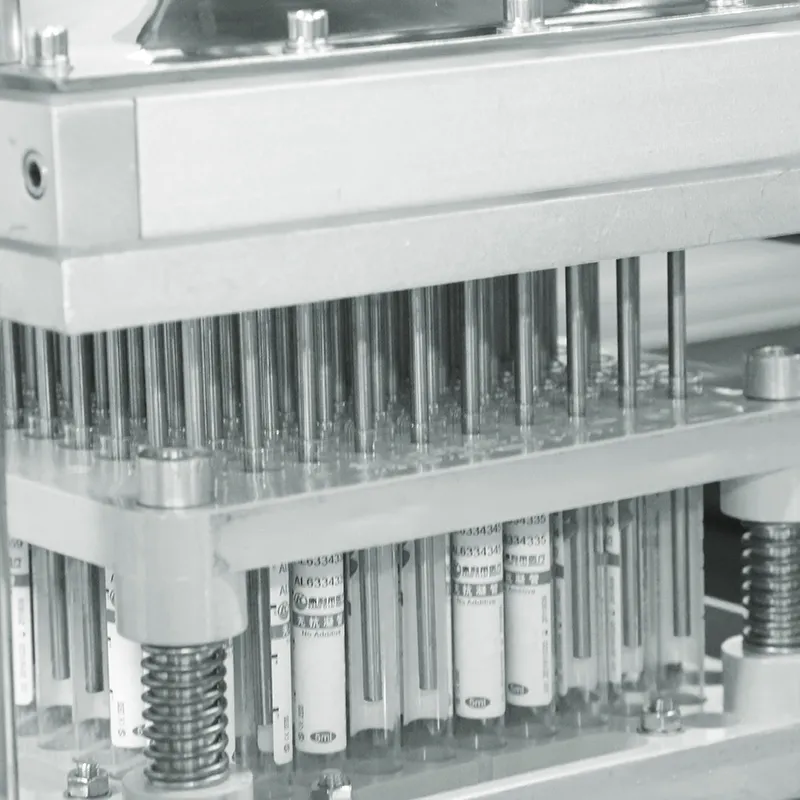

With a production speed of up to 18,000 tubes per hour, this blood collection tube assembly line offers the efficiency and precision needed for high-volume medical supplies manufacturing. The equipment smoothly transitions between vacuum and non-vacuum tube production by adjusting the vacuum settings to zero. Equipped with a pre-labeling system, it ensures accurate labeling for tubes sized 13×75mm, 13×100mm, and 16×100mm, and is compatible with PET, PP, and glass tubes.

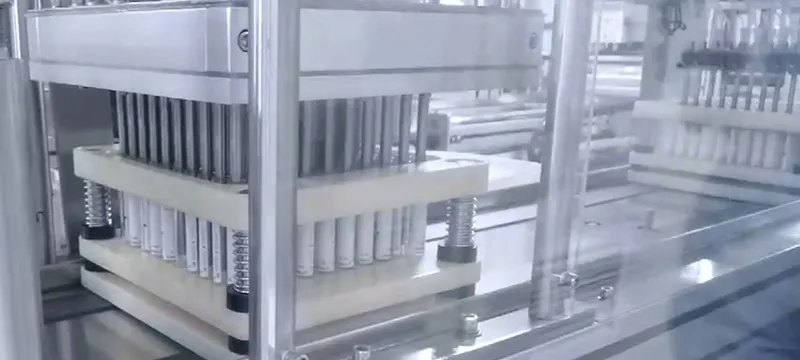

Work Flow

- Labeling (tubes without labels are automatically rejected)

- Tube loading

- Inversion detection

- Additive dosing (K2 EDTA/K3 EDTA, heparin, clot activator, sodium citrate)

- Capping

- Vacuuming

- Foam tray loading

- Heat shrink packaging

- Completion

Technical Specifications

| Model | H100+Pre-Labeling |

| Production capacity | 15,000-18,000 pcs/h |

| Tube size | Ø13×75mm, Ø13×100mm, Ø16×100mm, customizable (available in PET, PP, glass) |

| Cap size | As per client’s samples |

| Control system | PLC control with touch screen |

| Additive dosing system | K2/K3 EDTA: 10 sets of precision ceramic pump |

| Blood clot activator (BCA): 10 sets of precision ceramic pump | |

| Sodium citrate: 5 sets of precision ceramic pump | |

| Additive drying system | 4 PTC dust-free drying machines |

| Detection system | Rejection of unlabeled tubes |

| Inverted tube detection before additive dosing | |

| Alarm for shortage of foam trays | |

| Vacuum degree | Equipped with Leybold vacuum pump (Germany) and SMC vacuum control system (Japan) |

| Air consumption | Max. 1 m³/min Air supply pressure P:0.7Mpa≤P≤1Mpa |

| Power | 25kW/AC380V |

Frequently Asked Questions

What is the warranty period for the fully automatic blood collection tube assembly machine?

What is the warranty period for the fully automatic blood collection tube assembly machine?

Absolutely. We can customize the medical device assembly machines with password protection to safeguard settings and prevent unauthorized or accidental adjustments during production.

Can the blood collection tube assembly machine settings be password protected to avoid accidental changes?

Can the blood collection tube assembly machine settings be password protected to avoid accidental changes?

Yes, we offer comprehensive on-site installation and commissioning services. Our team ensures that the medical supplies assembly machine is set up and running efficiently, providing you with hands-on support for a smooth start.

Related Products

We provide efficient assembly solutions tailored to your medical device needs

Get in Touch

Which parts need to be replaced during routine maintenance, and how often?

Which parts need to be replaced during routine maintenance, and how often?

We provide a detailed maintenance manual. When a part reaches its maintenance cycle, the system will automatically display a reminder on the touchscreen interface, indicating the recommended part that requires service.

What brand of PLC is used in the control system? Does it support a multi-language interface?

What brand of PLC is used in the control system? Does it support a multi-language interface?

Our PLC and HMI (Human-Machine Interface) are from Siemens and support multiple languages. The default interface languages often used are Chinese, English, and Russian, but additional languages can be added upon request.

Does the equipment have remote monitoring or remote maintenance functions? Can it connect to an MES system?

Does the equipment have remote monitoring or remote maintenance functions? Can it connect to an MES system?

Yes. The automatic vacuum blood collection tube assembly’s system supports remote monitoring, allowing real-time viewing of equipment operating status. It can also output data to the client’s MES or ERP system.

Is the automatic vacuum blood collection tube assembly line equipped with fault alarms and shutdown record functions?

Is the automatic vacuum blood collection tube assembly line equipped with fault alarms and shutdown record functions?

Yes, it is.

About HONGREAT

Your Reliable Partner for Blood Collection Tube Assembly Solutions

- 220Partner of over 220 companies globally

- 40Exporting to more than 40 countries worldwide

- 20Over 20 years of experience in manufacturing blood collection tube assembly equipment

- 1010+ years dedicated to after-sales service

- 19Holder of 19 patents in blood collection tube machine technology