25,000-30,000 pcs/h

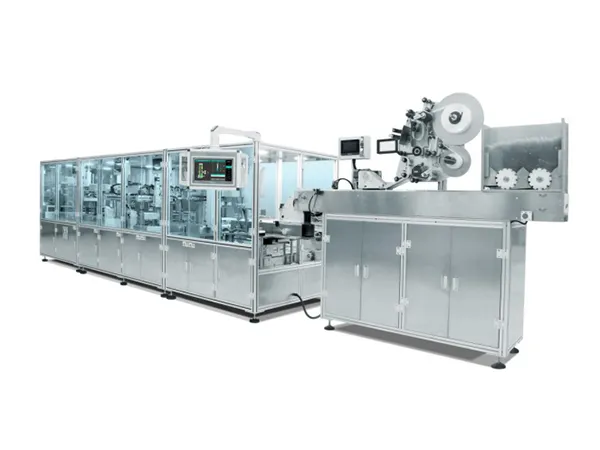

Automatic Vacuum Blood Collection Tube Assembly Line

High speed automatic production line for vacuum blood collection tube

Automatic Vacuum Blood Collection Tube Assembly Line

High speed automatic production line for vacuum blood collection tube

-

Production capacity 25,000-30,000 pcs/h

-

Tube size Ø13×75mm, Ø13×100mm, Ø16×100mm or customizable

(available in PET, PP, glass) -

Cap size As per client’s samples

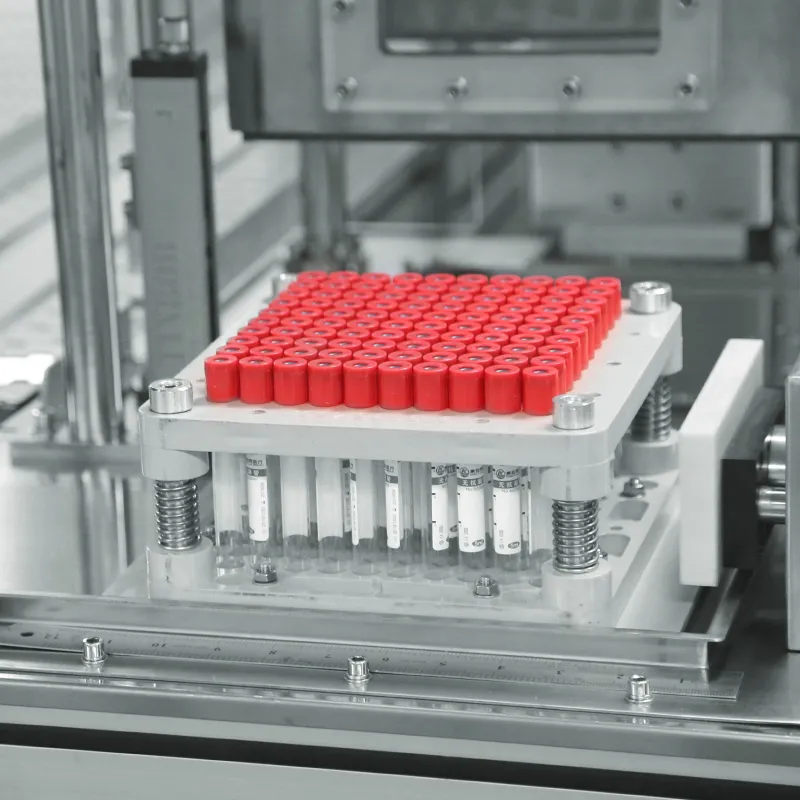

Finished Product Samples

Supporting high-speed production of 25,000 to 30,000 tubes per hour, this assembly line is built for large-scale operations. Whether for vacuum or non-vacuum disposable blood collection tubes, the assembly system adapts quickly by adjusting the vacuum settings to zero. This makes it suitable for manufacturing tubes made of various materials, meeting the demands of modern medical manufacturing environments. Its consistent output and flexibility help streamline production processes while maintaining accuracy.

Work Flow

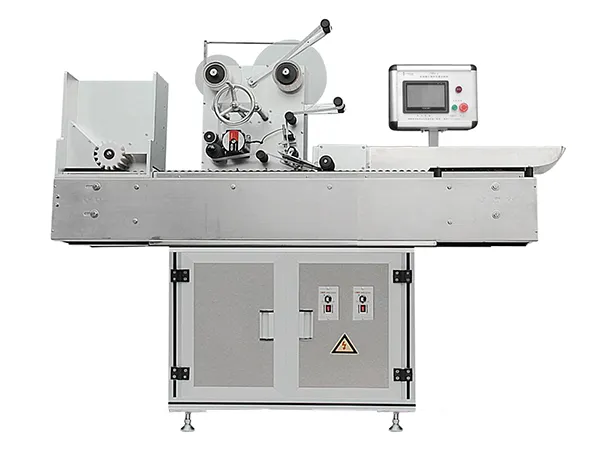

- Labeling (tubes without labels are automatically rejected)

- Tube loading

- Inversion detection

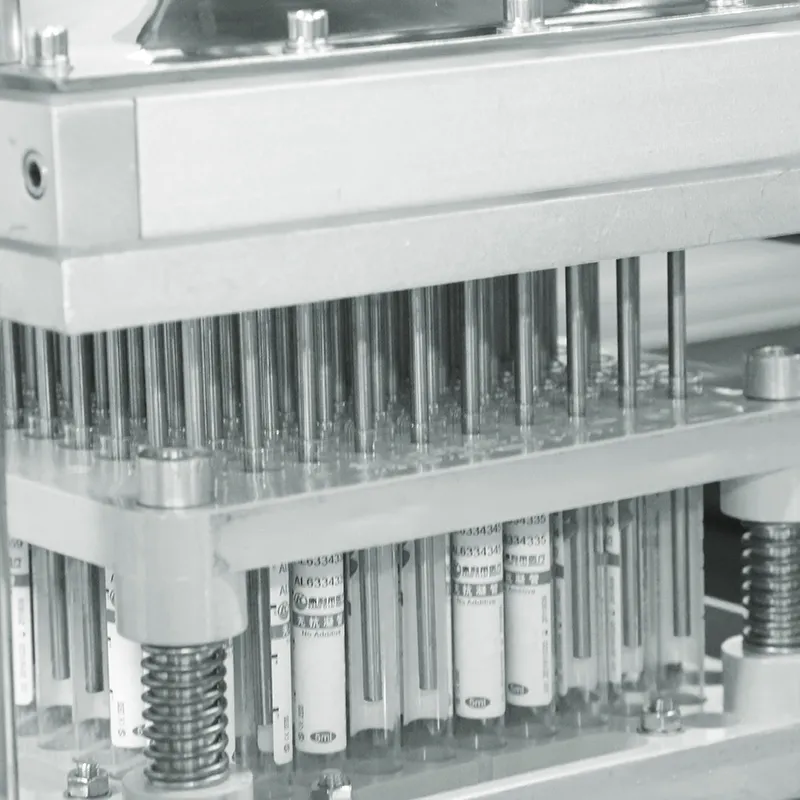

- Additive dosing (K2 EDTA/K3 EDTA, heparin, clot activator, sodium citrate)

- Capping

- Vacuuming

- Foam tray loading

- Heat shrink packaging

- Completion

Technical Specifications

| Model | H200 |

| Production capacity | 25,000-30,000 pcs/h |

| Tube size | Ø13×75mm, Ø13×100mm, Ø16×100mm or customizable (available in PET, PP, glass) |

| Cap size | As per client’s samples |

| Control system | PLC control with touch screen |

| Additive dosing system | K2/K3 EDTA: 10 sets of precision ceramic pump |

| Blood clot activator (BCA): 10 sets of precision ceramic pump | |

| Sodium citrate: 10 sets of precision ceramic pump | |

| Additive drying system | 5 PTC dust-free drying machines |

| Detection system | Rejection of unlabeled tubes |

| Inverted tube detection before additive dosing | |

| Alarm for shortage of foam trays | |

| Vacuum degree | Equipped with Leybold vacuum pump (Germany) and SMC vacuum control system (Japan) |

| Air consumption | Max. 1 m³/min Air supply pressure P:0.7Mpa≤P≤1Mpa |

| Power | 35kW/AC380V |

Frequently Asked Questions

What is the warranty period for the fully automatic blood collection tube assembly machine?

What is the warranty period for the fully automatic blood collection tube assembly machine?

The assembly machine includes a 12-month warranty, excluding wear parts. This warranty starts from the date the machine is received or as recorded on the delivery confirmation. Regular maintenance and proper usage can help extend the overall lifespan of the machine.

Do you provide on-site installation and support for the machine?

Do you provide on-site installation and support for the machine?

Yes, we offer comprehensive on-site installation and commissioning services. Our team ensures that the medical supplies assembly machine is set up and running efficiently, providing you with hands-on support for a smooth start.

Related Products

We provide efficient assembly solutions tailored to your medical device needs

Get in Touch

About HONGREAT

Your Reliable Partner for Blood Collection Tube Assembly Solutions

- 220Partner of over 220 companies globally

- 40Exporting to more than 40 countries worldwide

- 20Over 20 years of experience in manufacturing blood collection tube assembly equipment

- 1010+ years dedicated to after-sales service

- 19Holder of 19 patents in blood collection tube machine technology